Product Description

Product Description

| Bellows couplings are used where precise rotation, high speeds, and dynamic motion must be transmitted. They exhibit zero backlash and a high level of torsional stiffness, offering distinct performance advantages. |

Product Parameters

Company Profile

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing mechanical power transmission components. We Mighty is the branch of SCMC Group, a wholly state-owned company, established in 1980.

About us:

-3 manufacturing factories

We have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of material purchase and stock

We ensure both the quality and low cost for material and production.

-Strick quality control

We have strict process inspection and final production inspection to ensure the perfect quality.

-20 years of machinery experience

MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has gained good reputation from CHINAMFG customers.

FAQ

Q: Are you manufacturer or trading company?

A: We are factory of 20+ years and also do exporting business.

Q: How long is your delivery time?

A: Generally it is 4-6 days if the goods are in stock or 15-20 days with short stock based on the quantity.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer free sample but do not conclude the shipping cost.

Q: Do you support OEM/ODM?

A: Yes we do.

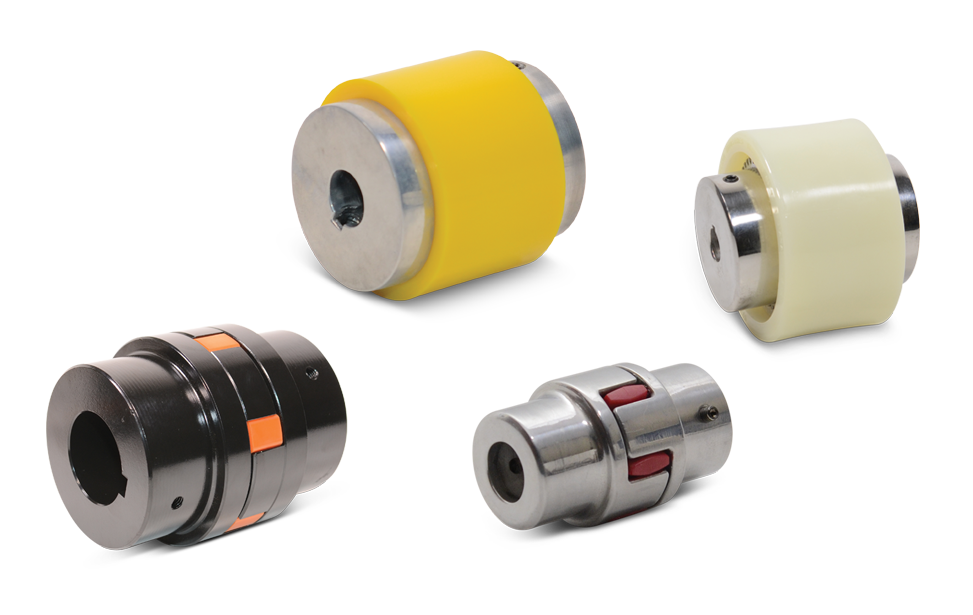

Q: Do you offer other types of shaft couplings?

A: Yes we offer a wide range of flexible and rigid couplings.

If you have another question, pls feel free to contact me without hesitation as below:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Exploring the Use of Elastomeric Materials in Flexible Motor Couplings

Elastomeric materials play a crucial role in the design and function of flexible motor couplings. These materials offer unique properties that make them well-suited for power transmission applications. Here’s an exploration of their use in flexible motor couplings:

1. Flexibility and Damping:

Elastomeric materials, such as rubber or urethane, are highly flexible, allowing them to absorb and dampen vibrations and shocks generated during motor operation. This damping property helps reduce resonance and noise, improving the overall performance of the power transmission system.

2. Misalignment Compensation:

Flexible motor couplings with elastomeric inserts can accommodate both angular and parallel misalignments between the motor and driven equipment shafts. The elastomeric material provides some radial compliance, allowing for smooth torque transmission even when the shafts are slightly misaligned.

3. Shock Absorption:

In applications where the motor or driven equipment is subjected to sudden shocks or impacts, elastomeric materials act as shock absorbers. They absorb and dissipate the impact energy, protecting the coupling and connected components from damage.

4. Low Inertia:

Elastomeric couplings typically have low inertia due to the lightweight nature of the elastomeric material. This low inertia reduces the rotational resistance and allows for rapid acceleration and deceleration of the connected equipment.

5. Corrosion Resistance:

Elastomeric materials are often resistant to corrosion, making them suitable for use in various industrial environments where exposure to moisture or chemicals may occur.

6. Electrical Isolation:

Elastomeric couplings provide electrical isolation between the motor and driven equipment shafts. This is advantageous in applications where electrical continuity must be avoided.

7. Easy Installation:

Elastomeric couplings are generally easy to install due to their simple and lightweight construction. They do not require special tools or complex alignment procedures, making them a popular choice in many applications.

8. Maintenance-Free Operation:

Properly designed and maintained elastomeric couplings can offer maintenance-free operation over extended periods. The absence of mechanical wear elements reduces the need for regular maintenance and replacement.

The use of elastomeric materials in flexible motor couplings provides numerous benefits, making these couplings suitable for a wide range of applications. Their ability to compensate for misalignment, dampen vibrations, and withstand shocks makes them particularly advantageous in situations where smooth and reliable power transmission is essential.

“`

Temperature and Speed Limits for Different Motor Coupling Types

Motor couplings come in various types, and each type has its temperature and speed limits. These limits are essential considerations to ensure the coupling operates safely and efficiently. Here are the general temperature and speed limits for different motor coupling types:

1. Elastomeric Couplings:

Elastomeric couplings, such as jaw couplings and spider couplings, are commonly used in a wide range of applications. They typically have temperature limits of approximately -40°C to 100°C (-40°F to 212°F). The speed limits for elastomeric couplings typically range from 3,000 to 6,000 RPM, depending on the specific coupling design and size.

2. Gear Couplings:

Gear couplings are known for their high torque capacity and durability. The temperature limits for gear couplings are usually between -50°C to 150°C (-58°F to 302°F). The speed limits for gear couplings can be as high as 5,000 to 10,000 RPM or more, depending on the size and design.

3. Disc Couplings:

Disc couplings provide high torsional stiffness and are often used in precision applications. The temperature limits for disc couplings are typically around -40°C to 200°C (-40°F to 392°F). The speed limits for disc couplings can range from 5,000 to 20,000 RPM or more.

4. Grid Couplings:

Grid couplings are known for their shock absorption capabilities. The temperature limits for grid couplings are usually between -30°C to 100°C (-22°F to 212°F). The speed limits for grid couplings typically range from 3,600 to 5,000 RPM.

5. Oldham Couplings:

Oldham couplings are often used to transmit motion between shafts with significant misalignment. The temperature limits for Oldham couplings are generally around -30°C to 80°C (-22°F to 176°F). The speed limits for Oldham couplings are usually up to 3,000 to 5,000 RPM.

6. Diaphragm Couplings:

Diaphragm couplings are suitable for applications requiring high precision and torque transmission. The temperature limits for diaphragm couplings are typically between -50°C to 300°C (-58°F to 572°F). The speed limits for diaphragm couplings can be as high as 10,000 to 30,000 RPM.

It is essential to check the manufacturer’s specifications and recommendations for the specific coupling model to ensure the coupling operates within its intended temperature and speed limits. Operating the coupling beyond these limits may lead to premature wear, reduced performance, or even catastrophic failure. Properly selecting a coupling that matches the application’s temperature and speed requirements is critical for reliable and safe operation.

“`

Can a Damaged Motor Coupling Lead to Motor or Equipment Failure?

Yes, a damaged motor coupling can lead to motor or equipment failure if not addressed promptly. Motor couplings play a critical role in connecting the motor to the driven equipment and transmitting torque between them. When a coupling is damaged, several potential issues can arise:

- Reduced Torque Transmission: Cracks, wear, or deformation in the coupling can result in reduced torque transmission from the motor to the driven equipment. This may lead to inefficient operation and underperformance of the machinery.

- Mechanical Vibrations: Damaged couplings can introduce vibrations into the system, leading to increased wear and fatigue on connected components, such as bearings and shafts. Excessive vibrations can cause premature failure of these parts.

- Misalignment and Stress: If the coupling loses its ability to compensate for misalignment, it can subject the motor and driven equipment to increased stress and loading. This can result in premature wear and failure of bearings, shafts, and other components.

- Overload on the Motor: In certain coupling designs, damage may result in a loss of overload protection. Without the safety mechanism, the motor may experience excessive loads, leading to overheating and possible motor failure.

- Increased Downtime: A damaged coupling can cause unexpected breakdowns and unplanned downtime for repairs, affecting productivity and overall operational efficiency.

- Safety Risks: In extreme cases, a severely damaged coupling may disintegrate during operation, posing safety risks to personnel and surrounding equipment.

To avoid motor or equipment failure due to a damaged coupling, regular maintenance and inspection are crucial. Visual inspections, vibration analysis, and monitoring of coupling performance can help identify signs of damage early on. If any issues are detected, it is essential to replace or repair the damaged coupling promptly to prevent further damage and ensure the reliable operation of the machinery.

Proper selection of high-quality couplings, appropriate for the specific application and operating conditions, can also reduce the likelihood of coupling failure and its potential impact on the motor and equipment.

“`

editor by CX 2024-04-29