Product Description

A beam coupling, also known as helical coupling, is a flexible coupling for transmitting torque between 2 shafts while allowing for angular misalignment, parallel offset and even axial motion, of 1 shaft relative to the other. This design utilizes a single piece of material and becomes flexible by removal of material along a spiral path resulting in a curved flexible beam of helical shape. Since it is made from a single piece of material, the Beam Style coupling does not exhibit thebacklash found in some multi-piece couplings. Another advantage of being an all machined coupling is the possibility to incorporate features into the final product while still keep the single piece integrity.

Changes to the lead of the helical beam provide changes to misalignment capabilities as well as other performance characteristics such as torque capacity and torsional stiffness. It is even possible to have multiple starts within the same helix.

The material used to manufacture the beam coupling also affects its performance and suitability for specific applications such as food, medical and aerospace. Materials are typically aluminum alloy and stainless steel, but they can also be made in acetal, maraging steel and titanium. The most common applications are attaching encoders to shafts and motion control for robotics.

Please contact us to learn more.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Is it Possible to Replace a Motor Coupling Without Professional Assistance?

Yes, it is possible to replace a motor coupling without professional assistance, but it requires some mechanical knowledge and proper tools. Here are the steps to replace a motor coupling:

1. Safety First:

Before attempting any maintenance or replacement, ensure the motor and driven equipment are turned off and disconnected from the power source to prevent accidents.

2. Identify the Coupling Type:

Determine the type of motor coupling currently installed in the system. Different coupling types may have slightly different installation methods.

3. Gather Necessary Tools:

Collect the necessary tools, such as wrenches, socket set, screwdrivers, and any other specific tools required for the particular coupling type.

4. Remove Fasteners:

Loosen and remove the fasteners that secure the coupling to the motor and driven equipment shafts. Keep track of the fasteners to ensure they are reinstalled correctly.

5. Disconnect the Coupling:

Disconnect the coupling from both the motor and driven equipment shafts. Depending on the coupling type, this may involve sliding the coupling off the shafts or unbolting it from the flanges.

6. Inspect the Coupling:

Inspect the old coupling for signs of wear, damage, or misalignment. This assessment will help determine if the coupling replacement is necessary.

7. Install the New Coupling:

Place the new coupling onto the motor and driven equipment shafts, ensuring it fits properly and aligns with any keyways or grooves.

8. Reattach Fasteners:

Tighten and secure the fasteners to hold the new coupling in place. Follow the manufacturer’s recommended torque values for the specific coupling model.

9. Perform Trial Run:

Before full operation, perform a trial run to check the coupling’s performance and ensure everything is working correctly. Monitor for any abnormal vibrations or noises.

10. Regular Maintenance:

After replacement, follow regular maintenance practices to inspect the coupling and the entire power transmission system for any signs of wear or issues.

While it is possible to replace a motor coupling without professional assistance, keep in mind that improper installation or failure to diagnose other underlying issues may lead to further problems. If you are unsure about the process or encounter difficulties during the replacement, it is always best to seek the help of a qualified technician or engineer to ensure a successful and safe coupling replacement.

“`

Do Motor Couplings Require Regular Maintenance, and If So, What Does It Involve?

Yes, motor couplings do require regular maintenance to ensure their proper functioning and longevity. Regular maintenance helps identify and address any potential issues before they lead to costly breakdowns or equipment failures. Here’s what regular maintenance of motor couplings typically involves:

1. Visual Inspection:

Perform a visual inspection of the coupling regularly to check for signs of wear, damage, or misalignment. Look for any cracks, corrosion, or deformation in the coupling components.

2. Lubrication:

Some motor couplings may have moving parts or bearings that require lubrication. Follow the manufacturer’s guidelines to apply the appropriate lubricant at recommended intervals.

3. Tightening Fasteners:

Check and tighten the coupling’s fasteners, such as bolts and screws, to ensure they are securely in place. Loose fasteners can lead to misalignment and reduce coupling efficiency.

4. Balancing:

If the motor coupling operates at high speeds, consider periodic balancing to prevent vibrations and ensure smooth operation.

5. Misalignment Check:

Inspect and correct any misalignment between the motor and driven equipment shafts. Misalignment can lead to premature wear and reduced coupling performance.

6. Replacement of Worn Parts:

If any components of the coupling show signs of significant wear or damage, consider replacing them with genuine spare parts recommended by the manufacturer.

7. Environmental Factors:

Consider the environmental conditions in which the coupling operates. If the coupling is exposed to harsh environments, take necessary precautions to protect it from dust, moisture, or chemicals that could cause corrosion.

8. Temperature Monitoring:

For high-temperature applications, monitor the coupling’s temperature regularly. Excessive heat can degrade elastomeric elements or lubricants.

9. Regular System Inspections:

In addition to focusing on the coupling itself, regularly inspect the entire power transmission system, including the motor and driven equipment, to identify any issues that may affect coupling performance.

10. Maintenance Records:

Maintain comprehensive maintenance records, including inspection dates, repair activities, and any replacements made. These records can help with future troubleshooting and provide valuable insights into the coupling’s performance over time.

Regular maintenance of motor couplings is crucial for ensuring safe and efficient operation. It helps prevent unexpected failures, minimizes downtime, and extends the overall lifespan of the coupling and connected components.

“`

What is a Motor Coupling and its Role in Connecting Motors to Driven Equipment?

A motor coupling is a mechanical device used to connect an electric motor to driven equipment, such as pumps, compressors, conveyors, and other machinery. Its primary role is to transmit torque from the motor to the driven equipment, allowing the motor to drive and control the operation of the connected machinery.

Function of a Motor Coupling:

The motor coupling serves several essential functions in the overall mechanical system:

1. Torque Transmission:

The main function of a motor coupling is to transfer torque from the motor shaft to the shaft of the driven equipment. As the motor rotates, it generates torque that needs to be efficiently transmitted to the machinery to produce the desired motion or work.

2. Misalignment Compensation:

Motor couplings can accommodate a certain degree of misalignment between the motor and driven equipment shafts. Misalignment may occur due to manufacturing tolerances, installation errors, or operational conditions. The coupling’s flexibility helps reduce stress on the motor and driven equipment’s bearings and prolongs their life.

3. Vibration Damping:

Some motor couplings, particularly those with flexible elements like elastomeric or rubber components, can dampen vibrations generated during motor operation. Vibration damping improves the overall system’s performance and reduces wear on connected components.

4. Overload Protection:

Motor couplings can act as a safety feature by providing overload protection to the connected machinery. In certain coupling designs, a shear pin or a similar mechanism may break under excessive load or torque, preventing damage to the motor or driven equipment.

5. Noise Reduction:

Well-designed motor couplings can help reduce noise and resonance in the system. By absorbing vibrations and minimizing backlash, the coupling contributes to quieter and smoother operation.

6. Efficiency and Reliability:

A properly selected and installed motor coupling improves the overall efficiency and reliability of the mechanical system. It ensures that the motor’s power is effectively transmitted to the driven equipment, resulting in smoother operation and reduced energy losses.

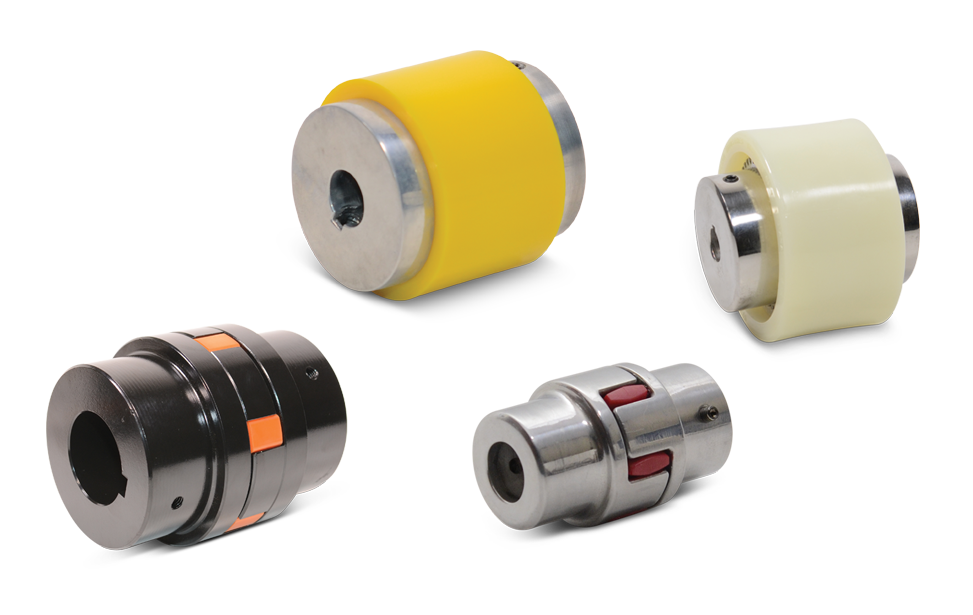

Motor couplings come in various types, including rigid couplings, flexible couplings, gear couplings, and more, each designed to suit specific applications and operating conditions. Selecting the appropriate coupling type is crucial to ensure optimal performance, prolonged equipment life, and enhanced safety in motor-driven systems.

“`

editor by CX 2024-01-15